ProShield® Aline: Aligning With Strengthened Sun Protection

Every painter knows the importance of precisely and uniformly spreading pigment on a target surface in order to achieve the desired visual results. This same principle applies to sunscreen application to skin; the only difference is that humans cannot see sunscreen active materials with the naked eye. Unlike an artist’s paints, sunscreen active materials interact with the UV region of sunlight instead of the visible light region. Therefore, sunscreens appear clear and colorless, effectively invisible to humans, after application. UV cameras have been used to assist in detecting and gauging sunscreen application quality; however, they are not widely accepted by consumers due to the inconveniences associated with carrying a camera just to apply sunscreen.

Because consumers are unable to directly perceive the quality of their sunscreen applications, the beauty industry needs to formulate sunscreens that can automatically assemble and form high quality, uniform layers upon even the most casual consumer application. This is especially important to those living in sun-abundant regions such as the Fresh Riviera (Nice) or those engaged in professions under extended exposure to the sun (such as construction). With corporate headquarters in Nyons, also known as Petit Nice, Proscien dedicates itself to the research and development of technology for robust and pleasant sun protection of skin.

ProShield® Aline technology was developed to enable precise and uniform distribution of sunscreen actives on skin for optimum sun protection. Sunscreens with ProShield® Aline ingredients achieve the best sun protection efficacy with the minimum amount of UV filters.

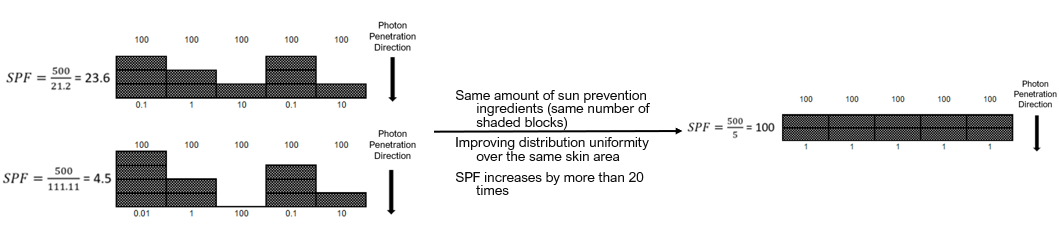

The objective of applying sunscreen is to prevent harmful UV rays from reaching the skin. As illustrated in Figure 1, UV prevention ingredients that are uniformly spread over a set skin area can be more than 20 times better at sun protection (in terms of SPF) than the same ingredients over the same skin area but with a nonuniform distribution.

ProShield® Aline technology was also developed to address the unavoidable UV absorption “leakage,” a concept that is inherent in all interactions between materials and light.

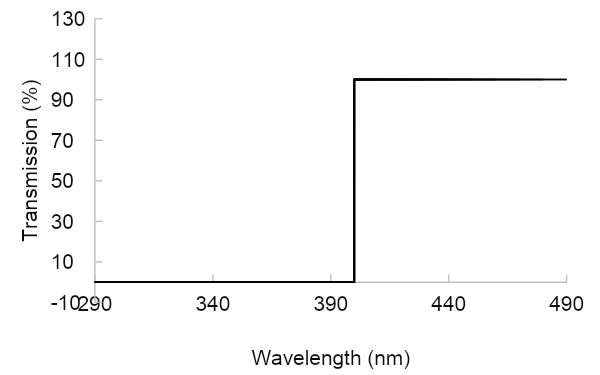

The perfect sunscreen layer would allow no transmittance in the UV region that humans are exposed to on the earth’s surface (290-400 nm). At the same time, it would immediately allow 100% transmittance at 400 nm and above (Figure 2). This is because humans can see light with wavelengths longer than 400 nm; consequently, any materials interfering with light longer than 400 nm appears to have a color. A colored sunscreen is cosmetically unacceptable to most consumers.

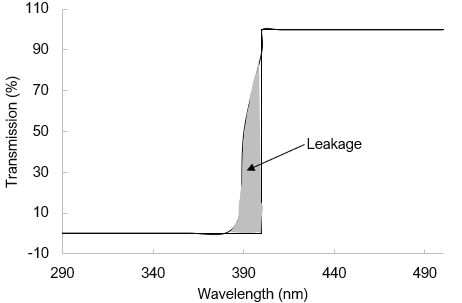

However, materials with an abrupt transmittance change from 0% to 100% at 400 nm (or any other wavelength) do not exist. The ability of a material to prevent light transmission is dependent on a collection of probabilities of its molecules’ interacting with photons. These probabilities do not change from 0% to 100% for all molecules at one wavelength. Therefore, even the best UV prevention materials can only achieve a gradual transition of transmittance from 0% to 100% right before 400 nm (Figure 3). The idea is to make this transition occur during as narrow a wavelength range as possible.

To ensure the product appears colorless to human eyes, the transition from 0% to 100% transmission needs to start before 400 nm in order to achieve 100% transmission at 400 nm. The region between the wavelength where the transmission starts to increase and 400 nm makes up an unavoidable “leakage” area. In this “leakage” area, harmful UV photons are allowed to reach human skin.

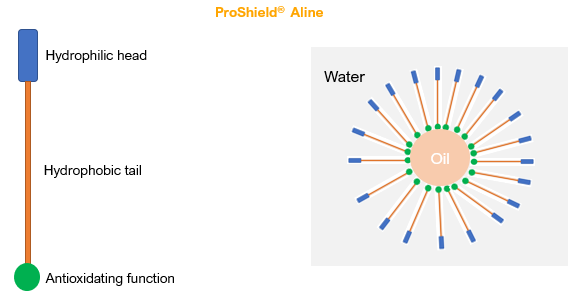

ProShield® Aline 1 (polyglyceryl-3 cocoate, feruloyl soy glycerides) and ProShield® Aline 1+ (polyglyceryl-10 decamacadamiate, feruloyl soy glycerides) were developed to solve these fundamental sunscreen performance challenges (Figure 4). Naturally-derived amphiphilic structures form liquid crystal alignments, imparting the needed rheological profiles to sunscreen so that uniform distribution of sunscreen filters can be attained spontaneously upon application to skin. As outlined earlier, uniformly distributed UV filters can achieve the highest sun protection performance possible at any set UV filter usage level. Natural antioxidants are attached to some of these amphiphilic structures, allowing them to also uniformly distribute throughout the sunscreen layer, effectively combating any oxidative stresses produced as the result of the unavoidable UV absorption “leakage”.

ProShield® Aline products enable strengthened sun protection performance with a minimum amount of UV filters through spontaneous and uniform sunscreen distribution over skin. ProShield® Aline products further prevent the consequences of the unavoidable UV absorption “leakage,” safeguarding the skin for maximum sunscreen performance.