ProActive® Tanche: Sustainable Extract from Olive Fruit

To reconnect with the land, pay homage to it, protect it, and make sure all we do is perfectly attuned to the spirit of nature, we have developed ProActive® Tanche in total synchrony with Nyons’ organic olive ecosystem.

The Nyons AOP (Protected Designation of Origin) olive terroir consists of 53 municipalities: 35 in southern Drôme and 18 in northern Vaucluse. This region hosts roughly 220,000 olive trees and 1,000 hectares of olive land; 42% of the olive trees are in a mountainous area that enjoys more than 2,700 hours of sunshine per year. The Nyons AOP stakeholders include 700 olive producers, 1 cooperative, 8 artisan millers, 3 private mills, 6 artisan table olive producers, and 60 private table olive producers.

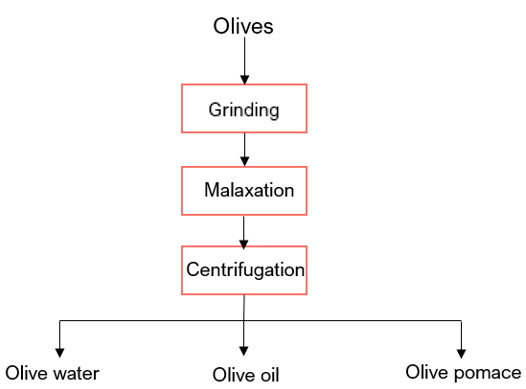

The milling of olive fruit for olive oil can be divided into three steps. The first step is grinding the olives. Crushing cleaned olives into a paste tears cells from the olive fruit and pits, facilitating the release of oil and other molecules from the vacuoles. Olives can be ground using stone mills, metal tooth grinders, or various kinds of hammer mills. The second step is malaxation. Slowly churning the olive paste for 20 to 45 minutes allows small oil droplets to coalesce into bigger droplets. However, the highest quality olive oil is produced at around 27°C without extended malaxation time. (Extending malaxation time, malaxing at a higher temperature, or adding water can all increase the yield of oil, but they also induce oxidation, reducing the quality of the oil.) The final step is separating the olive oil from the olive water and solids; this was previously done with presses and is now accomplished using centrifugation. Three-phase centrifuges, which are commonly used in Nyons, separate the oil, water, and solids individually. Two-phase centrifuges separate the oil from a wet paste.

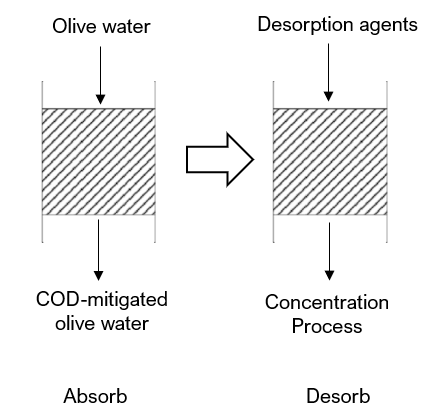

After separation, about 30-40% of fresh olives end up as olive water by weight. This water is rich in antioxidants and many other nutrients; however, olive water is commonly treated as an environmental nuisance. At Proscien, we have researched advanced extraction technologies to acquire phyto-active molecules from olive water and place them in a skin-friendly delivery medium. The result is ProActive® Tanche, a totally sustainable and highly effective skincare active ingredient. Our patent-pending extraction technology, illustrated below, also helps reduce environmental burdens by allowing for the easier return of olive water to the environment.

Olive trees, like all other plants, produce metabolites to act as a natural defense system. However, olive trees in particular are famously robust and resistant to insect or bacterial damages. As such, they can live for a long time, even in demanding environments. This longevity is caused by phyto-actives such as oleuropein and its derivatives. These phyto-actives are produced in olive plants and fruits and play critical roles in sustaining the life of the olive tree.

Complete understanding of the olive life cycle and associated metabolites allows us to maximize the plant’s benefits to humans. Table olives and olive oils are the two most common foods derived from this plant. However, to accommodate our sense of taste, over 90% of olive phyto-actives are eliminated during the production of both these food products. We at Proscien see this as an unnecessary waste. Therefore, we have developed technology and engineered methods to harness the valuable molecules that are normally discarded when producing olive-based foods. Delivering these life-sustaining molecules through skin can circumvent the obstacle posed by our taste buds. As such, ProActive® Tanche enables more comprehensive utilization of olive fruit for the good of humanity.

Olive phyto-actives come in many different structures, with the predominating family being phenolic antioxidants. Our ProSenteur® Olive delivers rich oil-compatible actives while ProActive® Tanche captures all the water-compatible actives. These, together with our Prolive® line of complete functional products based on olive oil esters, deliver complete olive benefits to skin.

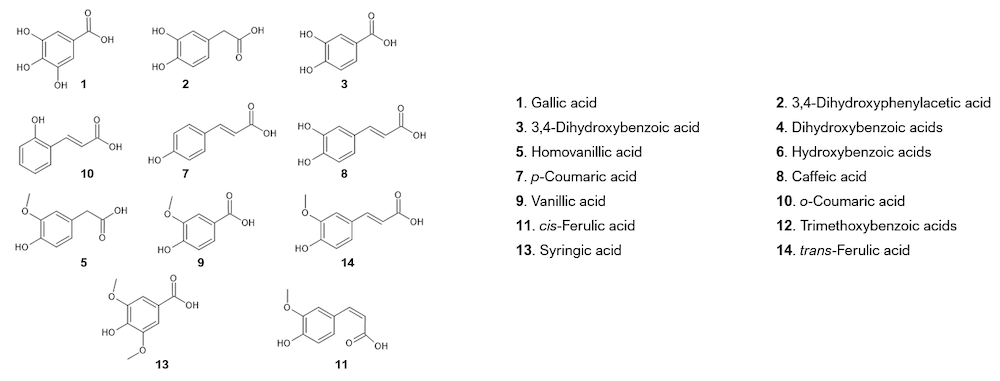

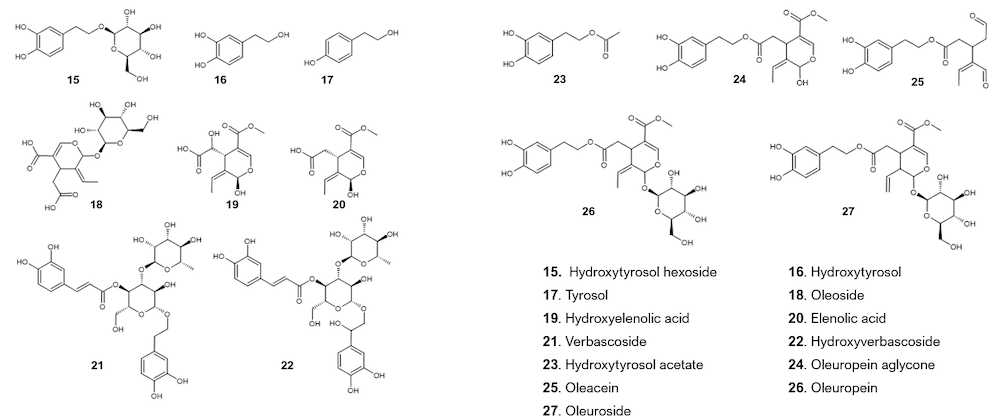

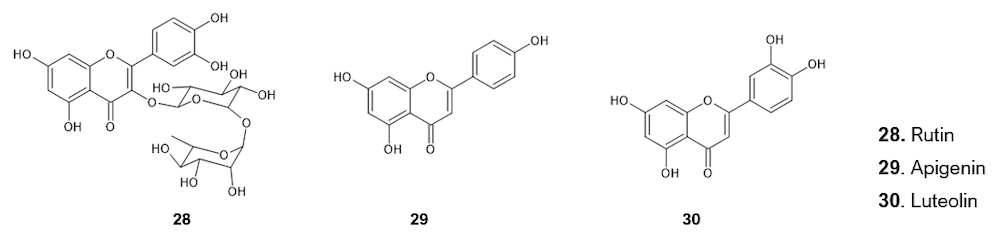

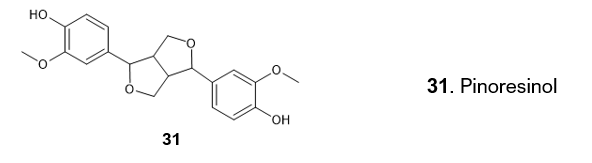

There are four major families of phyto-actives in olive water: phenolic acids, phenylethanoids and secoiridoids, flavonoids, and lignans.

Major phenolic acids and some of their chemical structures are shown here:

Phenylethanoids and secoiridoids are listed below:

Major flavonoids include the following:

The structure of one major lignan is displayed below:

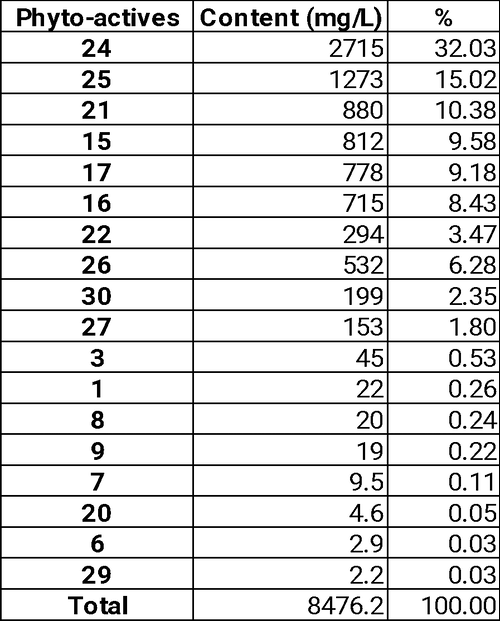

Analysis of a typical batch of ProActive® Tanche demonstrates that we recover most of these phyto-actives in high yields. In addition to providing the health benefits historically attributed to olive fruits, these active molecules have also been proven effective in many skincare applications.